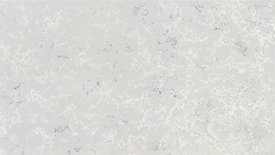

Quartz slabs are engineered masterpieces, combining 93% natural quartz with 7% resins and pigments to create durable,

elegant surfaces. Here’s a glimpse into their meticulous production process:

1. Selecting & Filtering

High-purity quartz sand is rigorously filtered to remove impurities like iron and clay, ensuring a flawless foundation.

2. Blending

The purified quartz is mixed with 6% polymer resins and pigments. Advanced blending techniques guarantee uniform color and texture, even for multi-veined designs.

3. Moulding

The mixture is poured into molds sized for standard slabs (e.g., 3200mm × 1600mm), ensuring consistent thickness and shape.

4. Pressing

Vacuum vibration compression eliminates air bubbles and compacts the material, achieving optimal density and strength.

5. Heating & Cooling

Slabs are cured in ovens at 85–110°C, then slowly cooled to prevent warping, ensuring structural stability.

6. Grinding & Polishing

Diamond-tipped grinders and polishers refine the surface to a mirror-like finish, with edges customized for design needs.

7. Filming

A protective film is applied to safeguard the slab during transport and installation, ready for its journey to your home.

From raw quartz to a polished slab, each step blends technology and artistry. The result? A versatile, long-lasting surface that elevates modern spaces.